Aligning and spacing ring shank framing nails in a project is crucial for ensuring a secure and structurally sound construction.

Here’s a general process to help you align and space ring shank framing nails effectively:

- Prepare the Work Area:

- Clear the work area of debris and ensure the surfaces to be joined are clean.

- Lay out and organize the materials to be fastened.

- Determine the Layout:

- Plan and mark the layout of the framing members, taking into account any design specifications, structural requirements, and building codes.

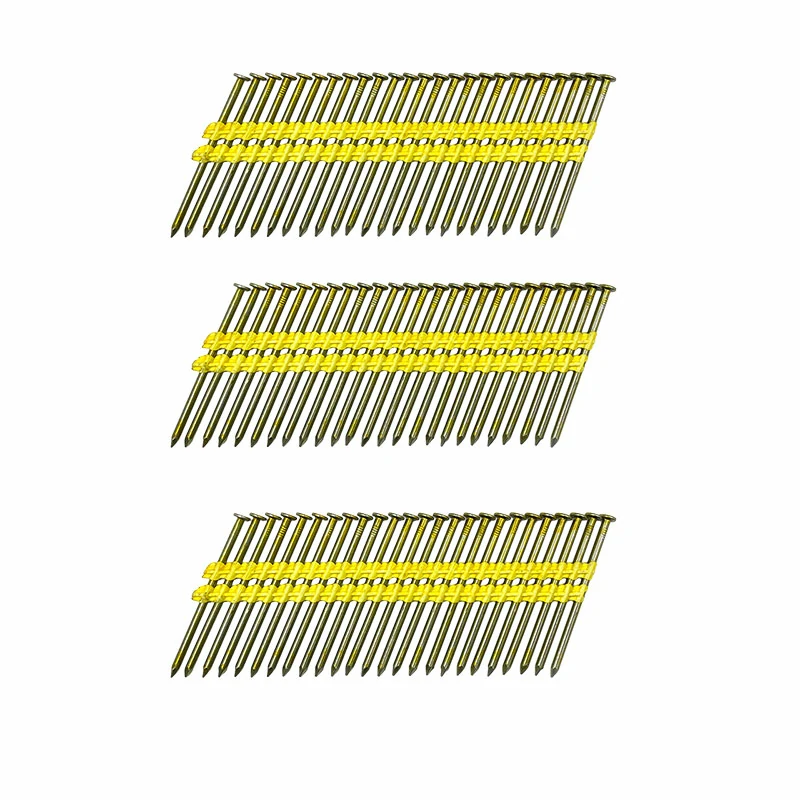

- Select the Right Ring Shank Nails:

- Choose ring shank framing nails that are appropriate for the project. Consider the length of the nails based on the thickness of the materials being fastened.

- Load the Nail Gun:

- If using a nail gun, load it with the ring shank framing nails according to the manufacturer’s instructions.

- Adjust Nail Gun Settings:

- Set the depth adjustment on the nail gun to ensure the nails are driven to the appropriate depth without over-penetrating or under-driving.

- Mark Spacing Guidelines:

- Use a pencil or chalk to mark guidelines on the framing members indicating where the nails will be driven. Spacing will depend on the project specifications and local building codes.

- Start at One End:

- Begin nailing at one end of the framing member and work your way to the other end. This ensures a consistent and orderly pattern.

- Maintain Consistent Spacing:

- Pay attention to the spacing between each ring shank nail. Consistency is essential for structural integrity and a professional appearance. ring shank framing nails You may use a spacing tool or guide for accuracy.

- Align Nails Vertically:

- Keep the ring shank nails aligned vertically along the center or designated location on the framing member. This helps distribute the load evenly.

- Consider Toe-Nailing Techniques:

- In situations where you need to toenail (drive nails at an angle), carefully align the nail to ensure it penetrates the desired location and does not compromise the structural integrity.

- Use Blocking and Bridging:

- In areas where additional support is needed, consider using blocking or bridging between framing members. This provides more nailing surface and enhances stability.

- Check Alignment Periodically:

- Throughout the nailing process, periodically check the alignment of the framing members to ensure they remain straight and plumb.

- Inspect and Adjust:

- After completing a section, inspect the work to ensure the nails are properly aligned, spaced, and driven to the correct depth. Make any necessary adjustments before moving on to the next section.

- Repeat for Additional Framing Members:

- Repeat the process for each framing member, following the layout and spacing guidelines for your specific project.

- Secure the Nailed Sections:

- Once a section is complete, secure it in place using additional fasteners or braces as needed.

Always follow safety guidelines, wear appropriate personal protective equipment, and adhere to local building codes and regulations during the framing process. The precision and care you put into aligning and spacing ring shank framing nails contribute to the overall strength and stability of the structure.